What is an FD Fan?

An FD fan, also known as a forced draft fan, is a type of fan that is used to move air or gas through a system. FD fans are typically used in industrial applications, such as power plants, factories, and HVAC systems.

(https://www.thermodyneboilers.com/forced-draft-fan/)

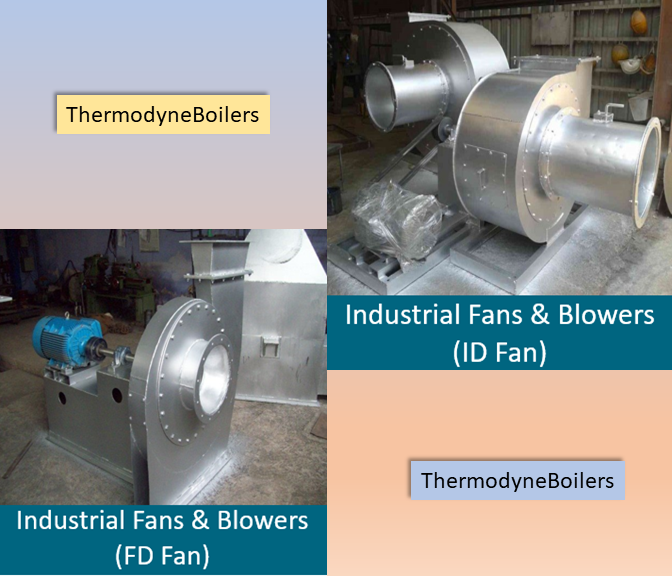

FD fan

How Does an FD Fan Work?

An FD fan works by using rotating blades to impart energy to the air or gas that is flowing through it. The blades are typically made of metal or plastic, and they are attached to a motor that spins them at a high speed. As the blades spin, they create a low-pressure area in front of them and a high-pressure area behind them. This pressure difference causes the air or gas to flow through the fan.

Types of FD Fans

There are many different types of FD fans, each with its own advantages and disadvantages. Some of the most common types of FD fans include:

- Axial fans: Axial fans have blades that are arranged in a straight line. They are typically used for low-pressure applications, such as ventilation and air conditioning.

(https://www.ebmpapst.com/jp/ja/products/axial-fans.html)

Axial fan

- Centrifugal fans: Centrifugal fans have blades that are curved. They are typically used for high-pressure applications, such as in power plants and factories.

(https://www.aerovent.com/products/centrifugal-fans/)

Centrifugal fan

- Mixed flow fans: Mixed flow fans have blades that are a combination of axial and centrifugal blades. They are typically used for applications that require a range of pressure capabilities, such as in HVAC systems.

(https://www.aerovent.com/products/inline-centrifugal-mixed-flow-fans/)

Mixed flow fan

Applications of FD Fans

FD fans are used in a wide variety of applications, including:

- Power plants: FD fans are used to move air through boilers and turbines in power plants.

- Factories: FD fans are used to move air through factories to provide ventilation and cooling.

- HVAC systems: FD fans are used in HVAC systems to move air through ducts and registers.

- Air pollution control: FD fans are used in air pollution control systems to remove pollutants from the air.

- Mining: FD fans are used in mining operations to move air through tunnels and shafts.

Advantages of FD Fans

FD fans offer a number of advantages over other types of fans, including:

- High airflow capacity: FD fans can move a large amount of air or gas in a short amount of time.

- High efficiency: FD fans are typically very efficient, meaning that they use a relatively small amount of energy to move a large amount of air or gas.

- Durability: FD fans are typically very durable and can withstand harsh environments.

- Low maintenance: FD fans typically require very little maintenance.

Disadvantages of FD Fans

FD fans also have some disadvantages, including:

- High noise level: FD fans can be very noisy, especially when operating at high speeds.

- Large size: FD fans can be very large, which can make them difficult to install and maintain.

- High cost: FD fans can be relatively expensive, especially when compared to other types of fans.

Conclusion

FD fans are a versatile type of fan that is used in a wide variety of applications. They offer a number of advantages over other types of fans, including high airflow capacity, high efficiency, durability, and low maintenance. However, they can also be noisy and large, and they can be relatively expensive.